Freeform Optics

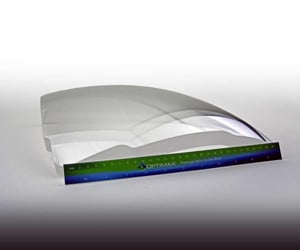

With an expansive team of technical experts, Optimax is one of the largest leading producers of freeform optics. This page contains a variety of Technical Papers surrounding Optimax System’s Freeforms Technical Expertise. Click here to find advice on your application, and read more about Optimax Freeform Manufacturing Technology.

Read More

Defining and Tolerancing Freeform Surfaces for ManufacturingFreeform optics presents unique challenges to designers and manufacturers. Understanding a vendor’s manufacturing and metrology capabilities is critical...Read More

READ MORE

Force controlled mid-spatial frequency error smoothing using machine learningFreeform optics have shown the ability to drastically increase optical design options, providing new solutions for space telescope and optics applications.READ MORE

Read More

Towards understanding tool influence function (TIF) spots during hemispherical sub-aperture tool polishingFreeform optics are typically fabricated using sub-aperture tool grinding and polishing. This polishing method requires a detailed understanding of the...Read More

Read More

Force responsive robotic controlled figuring and smoothing of lightweight freeform mirrorsOptical fabrication of freeform lightweight mirrors often results in mid-spatial frequency (MSF) and/or surface quilting surface errors.Read More

Read More

Freeform Monolithic Multi-Surface Telescope ManufacturingThe freeform monolithic multi-surface telescope design has all its off-axis optical surfaces manufactured from a single optical blank, resulting in truly...Read More

Read More

If you can’t measure it, you can’t make it: the importance of metrology in optics fabrication Optimax’s 30-year historyThis paper briefly tells the story of the importance of metrology in optics fabrication at Optimax, and highlights Wyko and Jim Wyant’s contribution to...Read More

Read More

Smoothing Mid-spatial Frequency (MSF) Errors on Freeform Optics with an Algorithm-based Robotic Platform Utilizing Deflectometry InputOptimax has developed the HERMES (High-End Robotic MSF Elimination System) a robotic platform that uses a machine learning algorithm to smooth parts....Read More

Read More

Fabrication of a 500 mm Extreme Freeform Conformal WindowThere is a potential need for large (>500 mm diameter) conformal windows for use on air, space, and watercraft.Read More

Read More

Design and Manufacturing Considerations for Freeform Optical SurfacesFreeform optical systems are becoming increasingly common due to new design and manufacturing methods. We present an example compact freeform optical system...Read More

Read More

Pushing Freeform Optical Manufacturing: Fabricating Optimax’s Largest Freeform ComponentSeveral challenges associated with part size and shape complexity were solved during the manufacture of the largest extreme freeform shape Optimax has...Read More

Read More

Using total error measurements of freeforms during manufacturing to aid in alignmentFreeform optics can enhance optical performance by reducing the number of elements, enabling lighter and more efficient systems, and by reducing aberrations.Read More

Read More

Effects of alignment errors on freeform surface irregularity and system performanceFreeform optics can be used in design to reduce optical system size and improve performance for asymmetric systems, but present new challenges for manufacturing, testing, and assembly compared to spherical or aspheric systems.Read More

Read More

Measurement of mid-spatial frequency errors on freeform optics using deflectometryFreeform optics have emerged as a new tool for optical designers and integrators. Manufacturing innovations are gradually increasing availability of...Read More

Read More

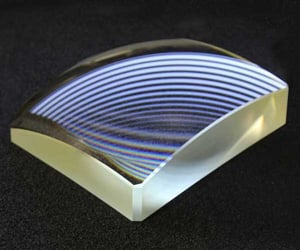

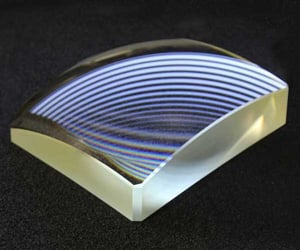

Fabrication of FreeformsOptimax has developed a robust freeform optical fabrication CNC process that includes generation, high-speed VIBE polishing, sub-aperture figure correction...Read More

Read More

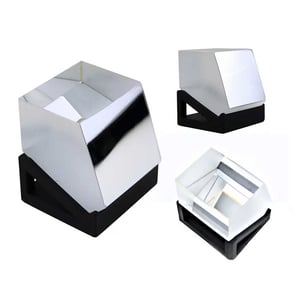

The Manufacturing of a Multi-surface Monolithic Telescope with Freeform SurfacesMonolithic multi-surface telescopes combined with freeform optical surfaces provide improvements in optical performance in a smaller footprint as compared to systems with spherical surfaces, while providing superior mechanical stability to traditional telescope assembliesRead More

Show more